| |

|

Heating Sets |

Controller Box |

In-feed Rollers |

In-feed Guide |

Heating Sets |

Press Roller |

Back Side Support |

Belt Conveyor |

|

|

1. Primary Technology Specifications

|

Seal speed : 0 - 13 m/min

Thickness of Material : 0 04 - 0.5mm (one layer)

Width for biding : 13mm ( 5 - 13mm should be specificated wihile order)

Length of seal : Un-limited

Temperature range : 0 - 300 °C

Adjustable range for the height of bag sealing : 140 - 600mm

Maximum loading of conveyor belt : 20 Kg the maximum capability of each bag : 5 Kg

Power supply : 220V/50Hz

Heating pipe for seal : 350W x 2 pieces

Heating pipe of print wheel : 100W x 2 pieces

Power of complete machine : 1030W

Exterior size : 1350L x 520W x 1280H (mm)

Package size : 1320L x 620W x 1440H (mm)

Net weight : 108 Kg

Gross weight : 185 Kg

DC Machine : 220V DC 123W

Cooling blower fan : 24V DC 11W Lettering cooling blower fan : 220V AC 9W |

|

2. Feature and Applicable range

|

FRL-600B type of (Standing) sequential plastic bag sealing machine is a perfect equipment for standing sealing with one layer plastic film in currently, as well as for aluminum-plastic, poser-plastic and composite plastics packaging bag. the unit has the characters of firm, tight and reliable sealing quality, goodly and lank sealing appearance, strong applicability, easy for operating, maintaining and servicing, low noise, easy for removing it, high efficiency and long working life.

It is a high-quality sealing machine which sealing tape could be used with metal barn or polytetrafluoroethylene fire resistant cotton tape (it should be specified while order) and each part could be adjusted freely. The unit is equipped with reliable thermistor and speed regulator that could do some adjustment according with the material or thickness of plastic bag, the temperature you need could constant automatically and could be used continuously. |

|

|

3. Primary structure and operational principle

|

The unit is composed with the parts of frame, reducing and driving mechanism, heater, cooler, knurling (typing) equipment, lifting and handling device, temperature controller and diginal speed controller. Every device should be operating and the temperature of upper and under heat block should rise after turn power supply and every switch on. Wind cooler begins to cool, conveyer belt operates and adjust the temperature and speed with need. Put packaging bag that filled two goods on conveyor belt, sent the selaing part of bag into the space between the tow operating sealing and deliver packaging bag to heaing zone synchronistically with coveyer belt held by the two sealing tape, The heat of heat block transfers to the sealing part of bag via sealing tape to make plastic film soften with the heat, then roll it with rolling wheel to make the soft part conglutinated reliably, cool it in cool zone to make the temperature on the surface of plastic films cool down. Finally, roll it with knurl wheel (or inking wheel) and produce net figure design (or print symbol) at the part of sealing, sent the sealed packaging bag out of the machine by conveyor belt and guide belt, and then the operaion is finished.

|

|

4. Inspection and Preparation before your using

|

4.1 This unit uses with single-phase EC power supply and equipped with three-pin plug for earthling of casing, you must check the power supply that if voltage meets the requirement of unit and the unit must be connected with ground protection correctly to ensure personnel safety.

4.2 Electro thermal pipe or electric machine should be effected with damp and the insulation resistant should debase while the first time of using or long pitch time of using, At this time, you should start-up the unit and warm it up with low temperature for half an hour, then begins to seal after you have ensured with different is no creep age.

4.3 Adjust elevate hand wheel of conveyor belt according with different altitude of packaging bags to get a right altitude with conveyor belt (put packaging bag filled with goods on conveyor belt and adjust the unit to make sealing parts match with sealing tape).

4.4 Adjust sealing gauge according with the sealing size you need and fix it up.

|

|

5.1 Turn power supply on, press power switch, conveyor belt switch, cooler switch, heater switch in order and check tat if every parts operated normally.

5.2 Adjust temperature controller according with material and thickness of packaging bag and set the temperature you need with knob, red lamp should light if the temperature is lower than set value and green lamp should light if the temperature meet set value, and then the unit should work the state of constant temperature automatically.

5.3 Seal could be operate if the temperature meets the needed temperature, normal produce could be operated only when the seal is lank, firm and without air leak and the figure design is clear.

5.4 Sealing temperature of the first time of test seal should be rose step by step to prevent the temperature is too high (especially for the operation of sealing with the one layer plastic film made up with normal polyethylene). It should be cleaned up if plastic film adheres on sealing tape after thawing to ensure the quality of seal and protect sealing tape.

5.5 Adjust speed of conveyor belt according to the set temperature. For the same packaging material, the speed could be increased accordingly if the temperature you set is high, and vice versa. Adjust compatible sealing temperature and speed according with material and thickness of packaging bag to achieve a high-quality and high efficiency of seal.

5.6 Measure one : Turn heating switch off and turn off all switches after 10 - 15 minutes of no load run.Measure two : Turn the deciliter knob of heat block, rolling wheel, cooling block right for 2 - 3 circles, this time, upper heat block, upper roller wheel and upper cooling block should be divided, then turn off all switches. |

|

|

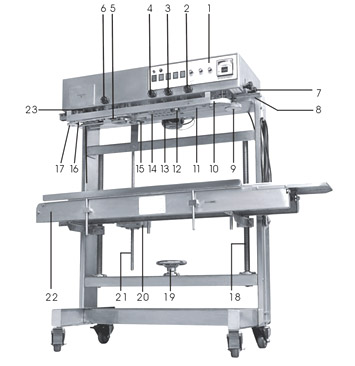

1. Control Panel

2. Deciliter Knob of Heat Block

3. Deciliter Knob of Rolling Wheel

4. Deciliter Knob of cooling block

5. Figure Design Wheel

6. Deciliter Knob of Figure Design Wheel

7. Adjusting Knob of Sealing Tape

8. Sealing Gague

9. Driver Wheel

10. Sealing Tape

11. Heat Block

12. Rolling Wheel

13. DC Machine

14. Cooling Block

15. Driver Wheel

16. Nylon Guide Tape

17. Guide Tape Wheel

18. Elevated Screws of Conveyor Belt

19. Elevated Handwheel of Conveyor Belt

20. Elevated Gear Case of Conveyor Belt

21. Elevated Polish Rod of Conveyor Belt

22. Conveyor Bel Frame

23. Lettering Devices |

|

|