How To Expand Your Contract Packaging Capabilities With Linx Printers

When it comes to contract packaging, companies are increasingly looking to consolidate their code printing requirements. Requiring multiple devices to print onto different sizes and substrates is costly and inefficient. Companies now need to offer a full service solution to be relevant and competitive.

When working with primary and secondary packaging, coding requirements may differ between the two, including printing on different substrates such as plastic, cardboard and metal for example. Traceability requirements such as visible, permanent codes to manage product recalls may be the same between the two, but code sizes will be different. If you are using multiple printers to achieve these requirements you could be wasting time and money.

New packaging trends

Companies also need to consider supporting new packaging trends such as new substrates, packaging product shapes and sizes and environmental issues such as reducing materials used. For example a product that offers “single serving portions” as well as the standard size potions will require a coder which can print the same information on different shapes and sizes of packaging. The information must be accurate and legible and permanent for traceability. It’s no use if a code can be smudged or wiped off a particular substrate.

Keeping costs down

Many contract packaging companies are introducing manufacturing techniques to cut costs and improve competitiveness. By implementing the right printing technology into your contract packaging business you can significantly cut costs, keep competitive and offer more to your customers.

With a single printing solution you can significantly cut cost in the following areas;

● Keep equipment costs at a minimum. Purchase and maintain a single coder that can complete all of your required tasks such as primary to secondary packaging Maximise efficiency. The production line is only as fast as the coder, so choose a coder with high reliability and long service intervals and which is quick and easy to maintain.

● Ensure you can switch product runs quickly to keep the production line moving for longer. Choose a coder with an intuitive and easy to use interface for quick set ups.

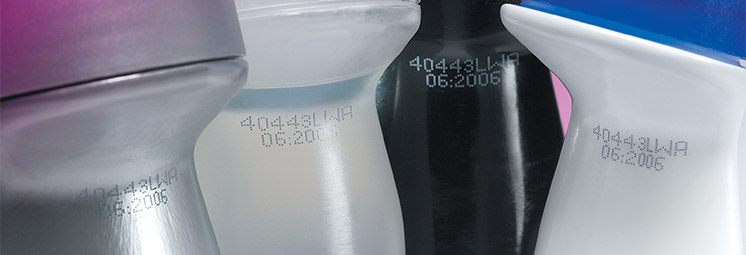

Linx CJ400

The Linx CJ400 continuous inkjet printer can print information, such as text, dates, and logos from just 1.8mm up to 20mm high, on a wide range of porous and non-porous substrates. This enables both primary and secondary coding with one easy to use, easy to maintain printer, making your contract packaging operation more efficient and cost effective.

● Reliability: Linx coders are industry leaders in reliability, with long service intervals and robust design.use For example Linx CIJ coders have an enclosure rating of up toIP65 to ensure the highest reliability. The Linx CJ400 can be self-serviced in minutes with no special training required.

● Ease of use: Linx coders have intuitive interfaces which make it easy to select and store messages. Ink changes are simple and mess-free and can be done without stopping the printer, saving you downtime.

● Mobility: The Linx CJ400 weighs just 13.5kg complete with fluids and can store up to 4 different line speed settings and up to 1000 messages, making it quick and easy to move between production lines and set up for coding.

● Versatility: Linx CIJ printers can print in any orientation – downwards, sideways, even upside down with no compromise on print quality or printer reliability.

● Flexibility: Linx CIJ printers are available with a range of ink colours and types for most porous and non-porous substrates, including ketone-free inks.