| |

|

DIR Technologies Brings 100% Inspection and Quality Control to Heat Sealing

At Pack/Pharma Expo Las Vegas September 28-30, DIR Technologies, a provider of quality and process control solutions for pharmaceutical primary packaging, along with machine manufacturer Shemesh Automation, used four little words to stop show attendees in their tracks.

“With in-line quality control…”

The reason for the phrase’s halting effectiveness was simple: the packaging industry has always known that inspection via sampling isn’t enough but, until now, didn’t have a technological alternative that could offer 100% inspection.

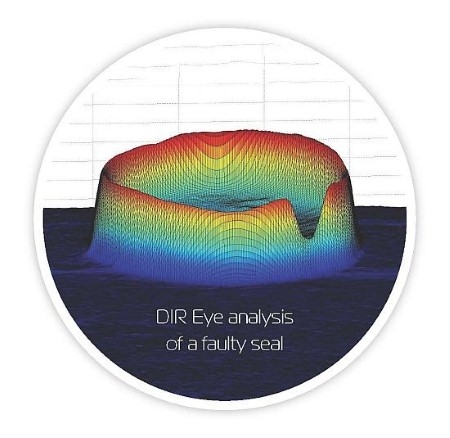

Enter the brand new DIR Eye, which was formally introduced at Pack Expo Las Vegas as an integrated feature on Shemesh’s SealPro Total thermo sealer. Visitors witnessed how the machine sealed each package and then immediately inspected the sealing quality without slowing down the packaging process whatsoever.

“You could see the light go on in their heads,” said Eran Sinbar, co-founder and Chief Technology Officer of DIR Technologies. “Visitors walked by the booth, probably saying to themselves: ‘Ok - another packaging machine.’ And then we told them it has 100% inspection. That’s when they snapped to attention and came close to learn more.”

Using the DIR Eye system, the SealPro Total automatically cuts the sealing laminate according to product sizes, ensuring both an accurate thermo seal and a correct sealing process.

“The SealPro Total is the first heat sealing packaging machine to provide a total experience, with sealing and inspection in one integrated unit,” said Shai Shemesh, Managing Director for Shemesh Automation. “This is the future for heat sealed packaging and, together with DIR Technologies, we are setting what we believe will become a new, heightened standard for packaging heat seal inspection.”

Package heat sealing is utilized in a broad range of industries: Wet wipes, yoghurt, spices, coffee capsules and cosmetics are just a few examples. As such, the possible applications of DIR Eye inspection are vast, and the availability of this technology could have a significant impact on industry-wide quality assurance standards.

The DIR Eye offers packagers the proposition that the packaging process is not complete without 100% sealing integrity inspection. Engineering best practices dictate that both input and output of any process are equally controlled, something that obviously cannot be attained via sampling, which generates statistical but incomplete data regarding process quality.

“It is a pleasure to work with forward-thinking companies such as Shemesh Automation,” said Sinbar. “The DIR Eye is a small, easy to integrate inspection unit whose benefits of real time inspection are obvious – it just wasn’t possible before and now it is. We expect that, very swiftly, other packagers will follow Shemesh’s example and add 100% inspection to their heat seal packaging systems.”

|

|

|

|